Filter Vessel Design Calculation

Filter vessel design calculation. AAiT Water Treatment By Zerihun Alemayehu. 90 05 90 337 113569 00408 d G d v b n d3 2 90 s g G n Where bk ht 3 2 d b v b design 13v v b backwash ra e m3 m2. Search for jobs related to Vessel design calculation or hire on the worlds largest freelancing marketplace with 19m jobs.

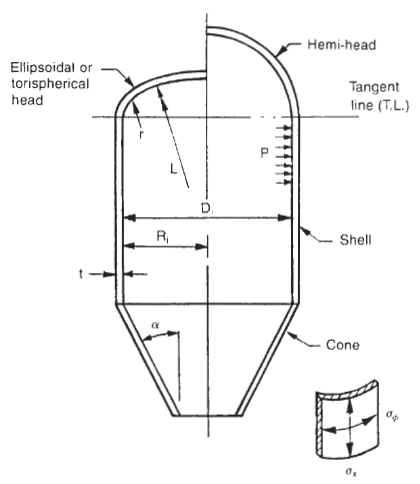

UG-37 Appendix 1-10 1-7 and div 2. Filter separator NOTE The design of gasliquidliquid three-phase separators is excluded from the scope of this DEP. Users of this DEP should first consult Section 2 Selection Criteria for GasLiquid Separators to familiarise themselves with the general design philosophy and the.

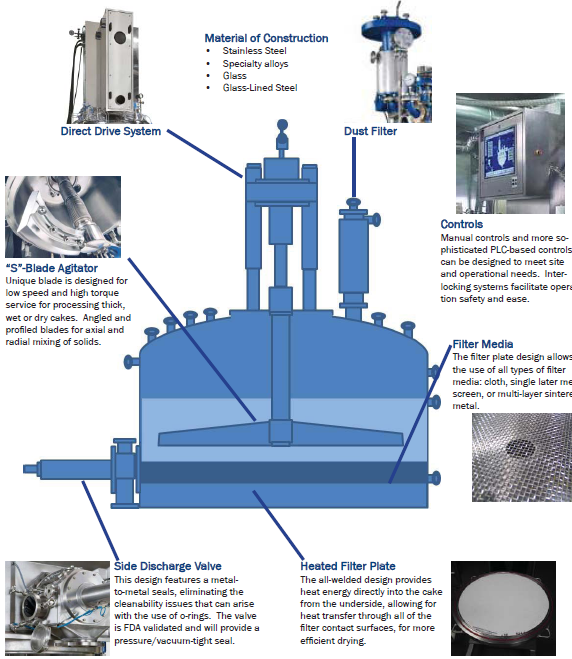

Examples include water pressure temperature flow rate available foot print and cubic feet of media per tank. These can only be used for interior pressure calculations. Filter is designed based on velocity consideration.

This guideline will provide a. Acceptable types of welded nozzle designs and other connections to pressure vessel shells heads and other geometries. Calculations of filter backwash rate The backwash flow rate is calculated using the following equations.

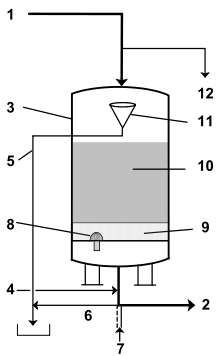

Recommended velocity for filtration is 10 mhr to 30 mhr. The maximum surface per filter is limited to 50 m2. It is used to remove suspended solids from raw water.

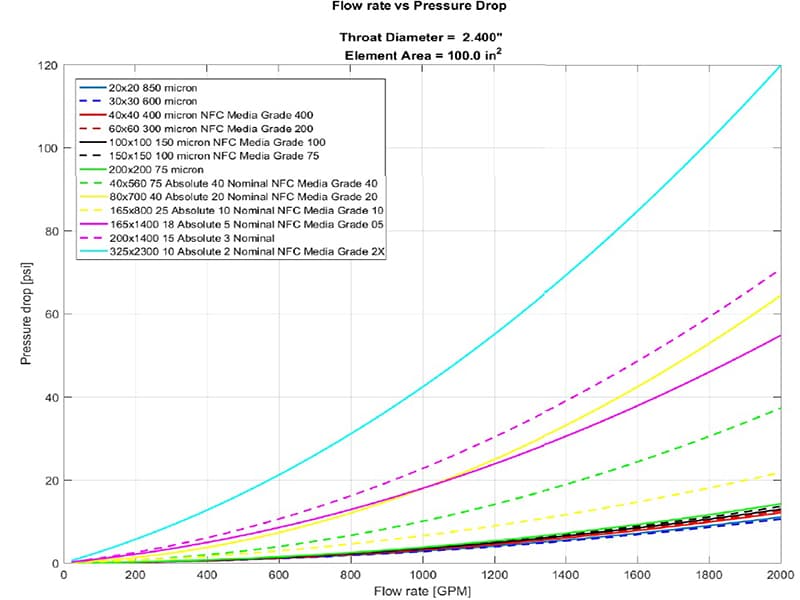

TYPICAL PRESSURE DROP CURVE FOR A BACKWASHED AND SEGREGATED BED Secondly it was necessary to calculate pressure drop in the filter disc that is going to support activated carbon bed in the column. Pressure Sand Filter Calculation Pressure sand filter is widely used filtration system for the removal of suspended solids and turbidity in the feed water. The design capacity of the water works is 035 m3s.

D 90 sieve size that passes 90 by weight µ dynamic 2viscosity. Mechanical structures are normally designed and calculated according to recognized standards and design codes usually as a part of a certification procedure.

The design loading rate is selected to be 160 m3m2 d.

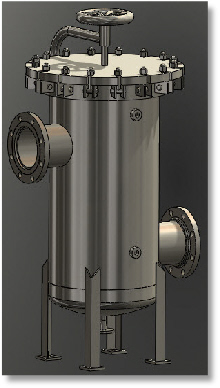

These can only be used for interior pressure calculations. This tool is useful in determining the diameter of the filter vessel. Acceptable types of welded nozzle designs and other connections to pressure vessel shells heads and other geometries. The method used for the analysis was WRC 537 local loads using Compress Pressure Vessel Calculation Software version 2018. For high operating pressures or high operating temperatures typically circular vessels are used. These can only be used for interior pressure calculations. Maticon are specialized in design and calculations of pressure equipment machine- and steel structures lifting equipment welded and bolted joints sports- and playground structures amongst others. For this subject DEP 31220512-Gen. Filter is designed based on velocity consideration.

For VOC contact time is 7 min. Calculations of filter backwash rate The backwash flow rate is calculated using the following equations. If we select velocity less than 10 mhr channeling will happen and velocity higher than 30 mhr will lead to high differential pressure. Pressure Vessel Nozzle with Repad Design Tool per. Design the number and size of filters and calculate the normal filtration rate. Recommended velocity for filtration is 10 mhr to 30 mhr. The structural calculations are.

Post a Comment for "Filter Vessel Design Calculation"